| Window Shape | Flat circular, flat rectangular, wedge, step, tube, and other special shapes | Materials | Optical grade single crystal sapphire |

| Aperture | >90% | Dimension Tolerance | +0.0/-0.2mm |

| Thickness Tolerance | +/-0.2mm | Flatness | custom |

| Surface Quality | Optional 80/50, 60/40, 40/20, 20/10, 10/5 S/D | Parallelism | 30 arcsec |

| Coating Options | Uncoated, Single Layer MgF2 AR Coating, and Other Custom Options |

Material Properties:

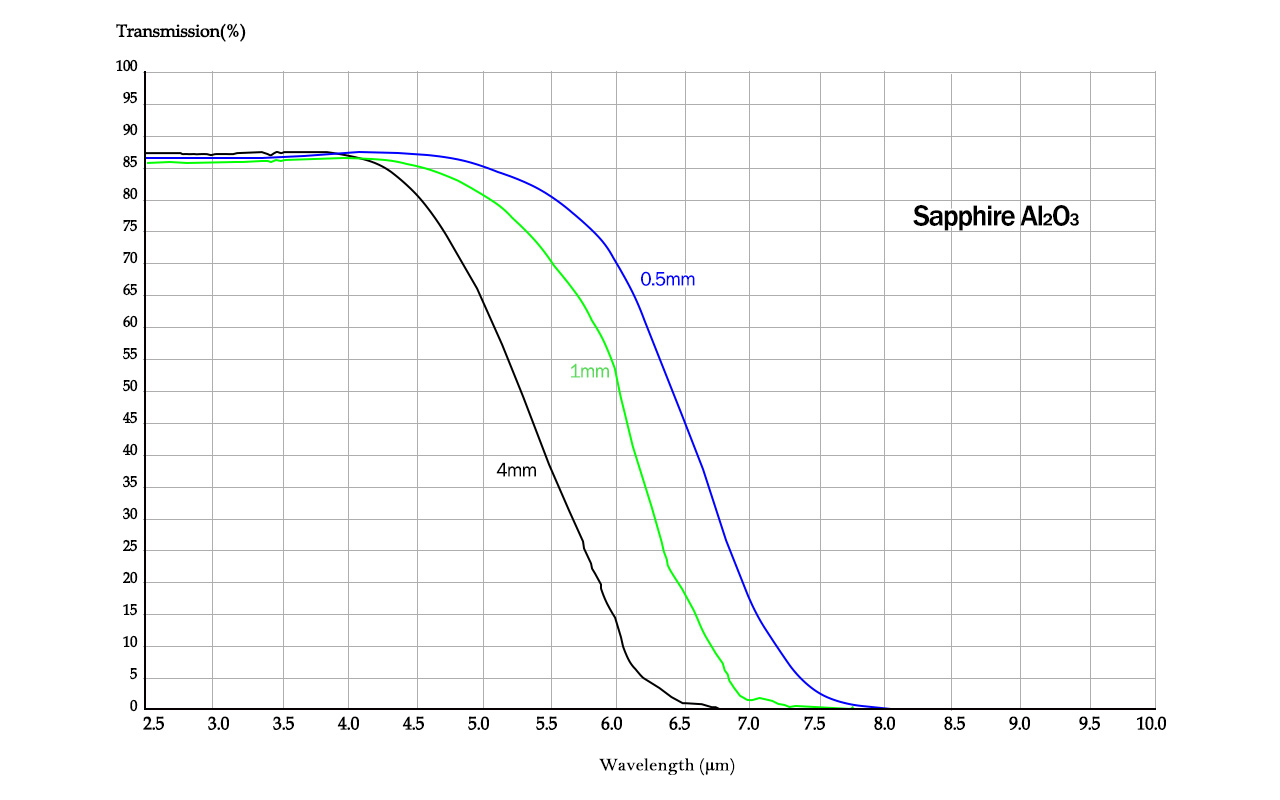

| Transmission Range | 0.15 to 5.5 μm | Refractive Index | No 1.75449; Ne 1.74663 @ 1.06 μm |

| Reflection Loss | 14% at 1.06 μm | Absorption Coefficient | 0.3 x 10-3 cm-1 @ 2.4 μm |

| Reststrahlen Peak | 13.5 μm | dn/dT | 13.1 x 10-6 @ 0.546 μm |

| dn/dμ = 0 | 1.5 μm | Density | 3.97 g/cc |

| Melting Point | 2040°C | Thermal Conductivity | 27.21 W m-1 K-1 @300K |

| Thermal Expansion | 5.6 (para) & 5.0 (perp) x 10-6 /K * | Hardness | Knoop 2000 with 2000g indenter |

| Specific Heat Capacity | 763 J Kg-1 K-1 @ 293K | Dielectric Constant | 11.5 (para) 9.4 (perp) @ 1MHz |

| Youngs Modulus (E) | 335 GPa | Shear Modulus (G) | 148.1 GPa |

| Bulk Modulus (K) | 240 GPa | Elastic Coefficients | C11=496 C12=164 C13=115 C33=498 C44=148 |

| Apparent Elastic Limit | 300 MPa (45,000 psi) | Poisson Ratio | 0.25 |

| Solubility | 98 x 10-6 g/100g water | Molecular Weight | 101.96 |

| Class/Structure | Trigonal (hex), R3c |

Sapphire Windows, featuring reliable mechanical/thermal/chemical robustness, large dielectric constants, and broad optical transmission from 150-5500nm, are excellent as both optical windows and protective windows in application contexts of more stringent requirements and extreme conditions.

The most distinctive feature of the sapphire is its unrivaled hardness and ruggedness. The Mohs Hardness of Sapphire is 9, and it is the second hardest material that exists, ranking next to diamond. Sapphire windows are in extreme resistant to scratches and abrasions sapphire windows can, on few occasions, be damaged using other materials other than sapphire itself. This means sapphire windows could ensure clear optical apertures and maintain lucid sights even under attack sand /grit and are exquisite for applications that will encounter splattering abrasive particles, such as drilling viewport windows, protective laser processing windows, and gun sights.

Due to the firm internal covalent bonding of sapphire, windows made from sapphire could be manufactured into much thinner pieces without fracture than the counterparts made from dielectric materials, and capable of withstanding high pressure. For instance, sapphire windows are often selected in avigation and deepwater contexts.

Furthermore, sapphire is high-temperature-tolerable with a working temperature limit of up to 1600℃ and a melting point of 2000℃. Its high thermal conduction also endows sapphire windows with a unique advantage in handling high-temperature situations compared to other optical materials. Sapphire windows, therefore, are great options for high-temperature plasma chambers, combustion chambers, etc.

Sapphire windows contain solid chemical inertia to common acids/alkalines, with the sole exception being hot caustic salts. Sapphire outperforms other materials in coping with corrosive chemicals and erosive atmospheres, hence expanding the usage of sapphire windows into the domain of pharmaceuticals, medicines, and chemical facilities.

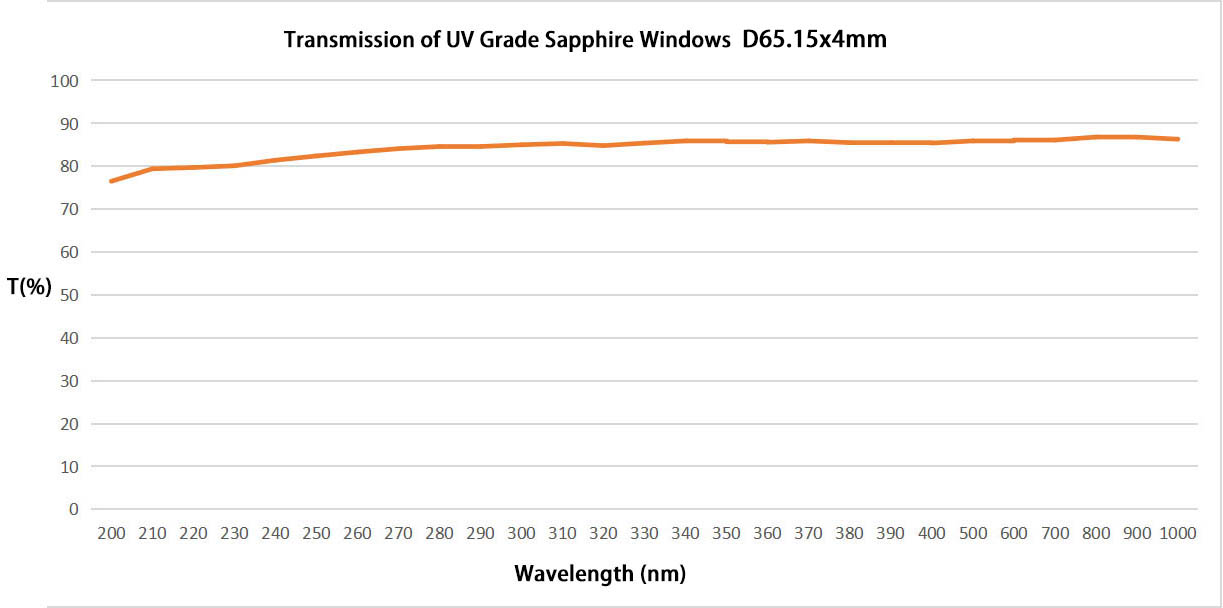

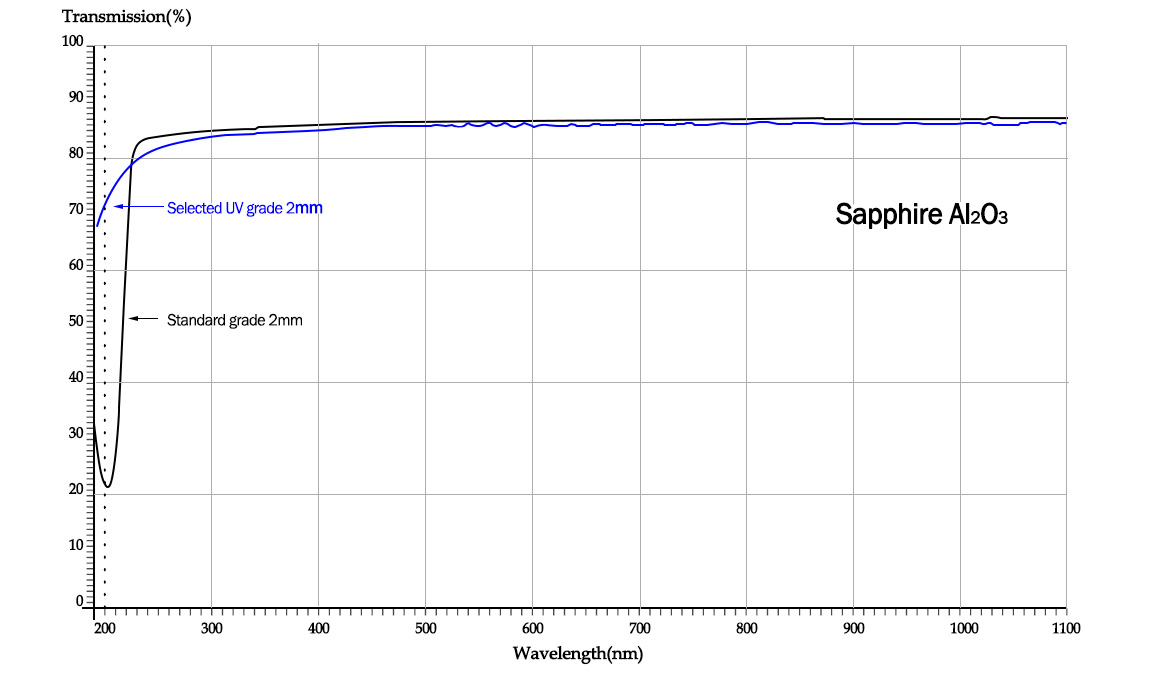

Besides, sapphire windows' broad spectral transmission encompasses 150nm-5500nm. Compared with the two common optical glass materials N-BK7 and UV Fused Silica, the transmission spectrum of N-BK7 is 350nm-2200nm, and UV Fused Silica 200-2200nm, sapphire excels N-BK7 with better UV functions and broader IR transmission and UV Fused Silica with less IR absorption. Sapphire windows could be utilized in critical optical operations of multi-spectrum.

Shalom EO offers various forms of Sapphire Windows made of Single Crystal Sapphire.

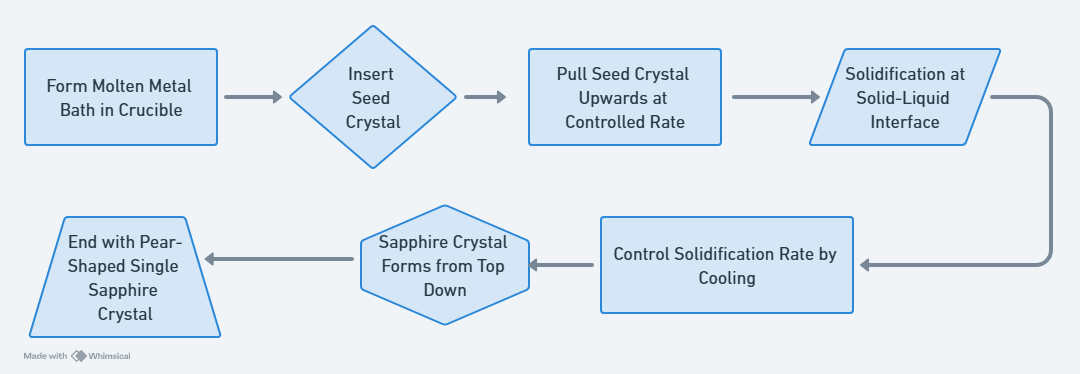

Our single crystal sapphires are grown using the KY (Kyropoulos) method and the SAPMAC (Sapphire Growth Technique With Micro-Pulling And Shoulder Expanding At Cooled Center) method. The Kyropoulos growth method is characterized by a temperature control process to enable the gradual cooling of the single sapphire crystal, resulting in less thermal stress and mechanical shock, while the SAPMAC method is a further refined version of the KY method that excels at growing large size crystals. (switch to the resource tab for a more detailed introduction to the KY and SAPMAC methods.) These two cutting-edge sapphire growth methods allow us to deliver sapphire windows of large sizes, and high purities without visible fractures, bubbles, and sub-grain.

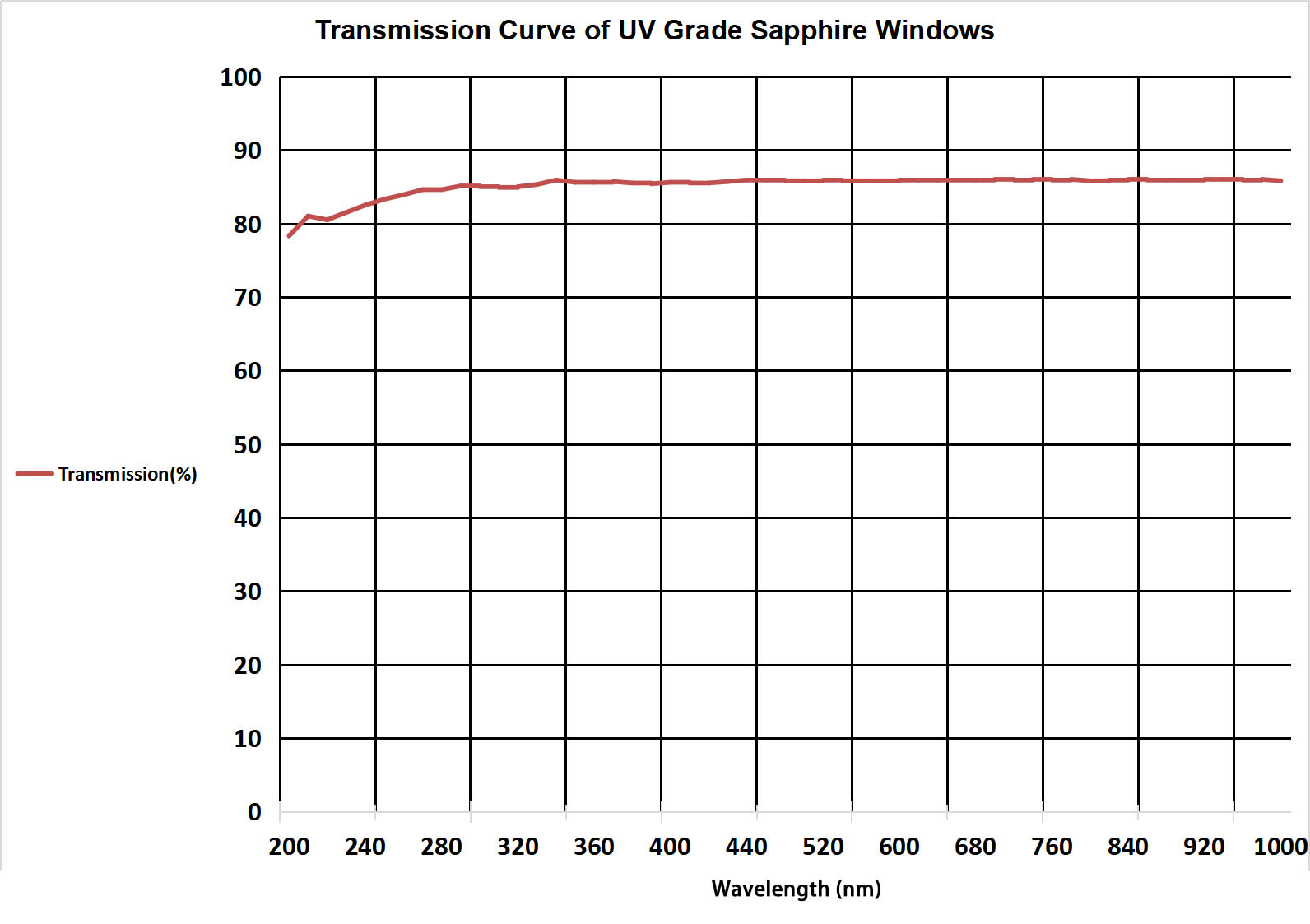

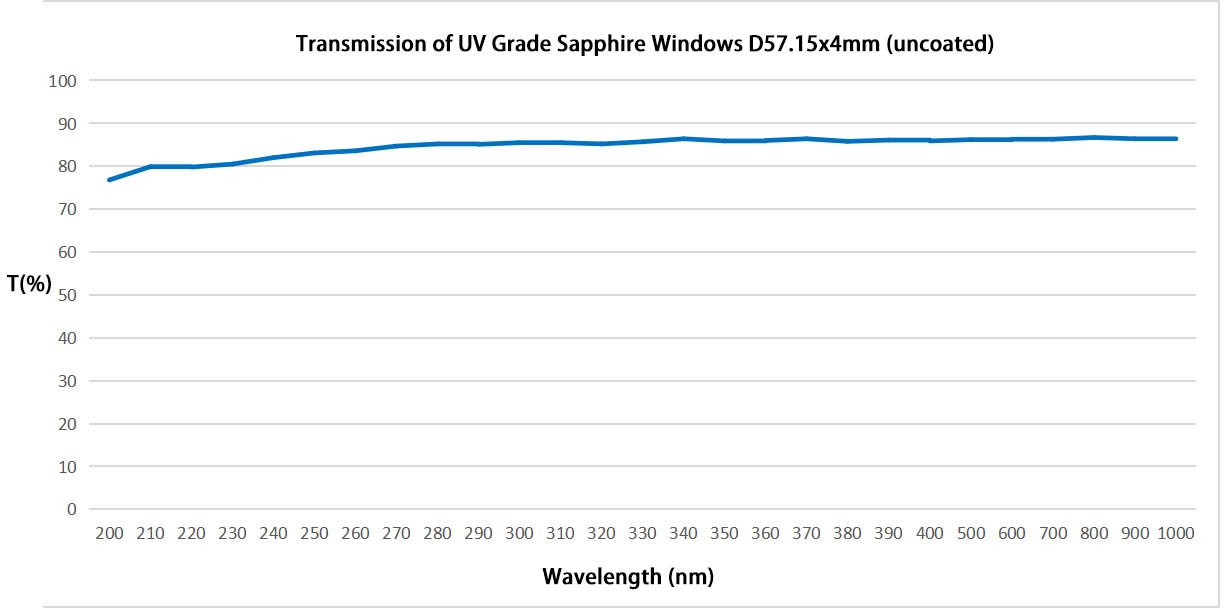

UV-grade sapphire windows with no UV absorption peaks and high UV darkening resistance are also available in Shalom EO. During the growth process of sapphire, especially in high-purity and high-temperature conditions (such as over 2000°C), the sapphire is often grown in an environment with a reducing atmosphere. This can lead to the loss of oxygen atoms, creating F-centers where oxygen vacancies are created in the sapphire crystal, and the vacancies are filled by electrons. To address this issue, Hangzhou Shalom EO offers UV-grade sapphire windows, the sapphire is specially fabricated with eliminated oxygen defects to exhibit no absorption peak at the critical 200 nm UV wavelength. You might view the transmission curves under the technical imaging tab).

Large aperture sapphire windows with diameters up to 300mm are available, and surface qualities of 60/40, 40/20, 20/10, and Scratch/Dig are optional according to the precision requirements of your interest. We are also capable of providing high-precision ultra-thin sapphire windows with a large diameter-to-thickness ratio.

Blank sapphire substrates and windows coated single film MgF2 coatings and other AR coatings could also be furnished to increase transmission. Z-cut (or C-cut) <0001> sapphire windows with the c-axis parallel to the optical axis to avoid birefringence in critical optical uses, and random-cut sapphire windows are both available. With state-of-the-art technologies, you can experience optical excellence with a diverse range of sapphire window products: Optical Sapphire Windows (flat circular, flat rectangular, sapphire wedge windows, sapphire step windows), Protective Sapphire Laser Windows, sapphire windows for sight glass and packages of machine interiors, metalized sapphire windows with nickel, chrome, and gold films on the window edges. Besides, you might also read more about our off-the-shelf sapphire windows.

Available Sapphire Window Kinds:

1. Optical Sapphire Windows:

Various shapes and forms of flat sapphire windows (circular, rectangular) and sapphire wedge windows, sapphire step windows are available in Shalom EO. The sapphire wedge windows comprise two unparallel planes and are utilized to deflect the incident beam to a specified direction at a certain deflection angle. Sapphire step windows are designed with stepped structures to ease the mounting onto certain mechanics (e.g. flanges).

2. Protective Sapphire Laser Windows:

Sapphire Protective Laser Windows are often utilized in laser processing as the front optic, protecting the laser lens from spattering substances during the processing course. Single crystal sapphire windows are suitable for the purpose due to their high-temperature endurance, outstanding mechanical hardness, and insusceptibility to high-power laser-induced damages.

Shalom EO provides sapphire laser windows with standardized specifications compatible with the laser machines from the world-leading laser producers. AR coatings with high thermal damage thresholds are procurable.

3. Other Special Sapphire Windows:

Sapphire windows could also be utilized as the sight glass and packages of machine interiors, insulating the machines from potential impairments resulting from high pressure, high temperature, chemical corrosion, etc. in applications such as underwater detection, high-pressure containers, oil deposit testing, and chemical operations.

Shalom EO offers High-pressure Protective Sapphire Windows, Deep Water Sapphire Windows, Corrosion-resistant Sapphire Tubes, and Sapphire Watch Glasses.

4. Metalized Sapphire Windows:

Metalized sapphire windows are furnished with metal films around the edges to enable hermetic soldering into metal housings. Metalized windows are often incorporated into endoscopes.

Shalom EO provides metalized sapphire windows of common endoscopic dimensions.

Application Notes:

C-cut, A-cut, and Random-Cut Sapphire Windows:

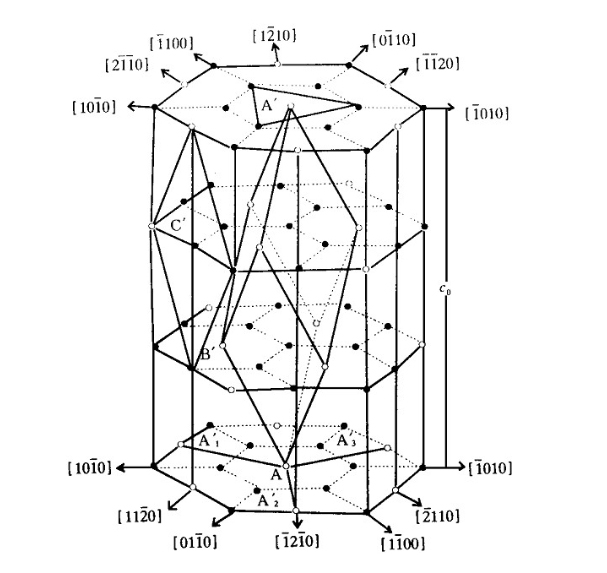

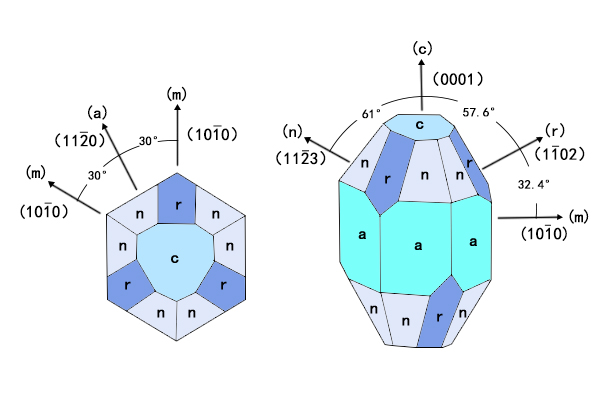

The orientation of a crystal is a vector describing a random line connecting two nodes on the lattice. Due to the anisotropic nature of crystals, the distribution and the arrangement manner of the atoms change along different directions or upon different lattice planes. The result of this is that the properties and behaviors, even of the same crystals, but with different orientations will differ to a significant extent. This is the reason of choosing the proper orientations and cutting planes of crystals is critical when using crystals to produce various components and elements.

The Sapphire crystals utilized to produce sapphire windows of different functions will be grown and cut/sliced with an engineered orientation, and the orientation is often determined because it will optimize the crystal’s performance to achieve the intentions of interest.

The lattices within the sapphire are arranged in a hexagonal structure. When a sapphire element is produced, the direction of its inner architecture affects the functionalities of the element.

Figure 4.The Lattice Structure of Sapphire and Common Sapphire Crystal Orientations

C-Cut Sapphire Windows has an orientation index of (0001). The sapphire is cut in a direction perpendicular to the c-axis. The c-axis is the optical axis of sapphire. Light projected along the direction of the optical axis minimizes birefringence. In practice, the light will be incident with a perpendicular angle to the apertures of the sapphire windows, which means the light will travel inside the sapphire windows parallel to the optical axis, eliminating the birefringence effect. C-cut sapphire windows are often chosen for critical optical applications (e.g. laser windows). C-cut sapphire is sometimes called zero-degree sapphire, or z-cut sapphire.

A-cut Sapphire Windows are selected when scratch resistance and hardness are important.

There are also Random-cut Sapphire Windows. Random-cut implies the sapphire ingots are cut or sliced with no specific regard to directions. Random cut sapphire window orientation is when the intrinsic birefringence of the sapphire window is acceptable if and when there are no stringent requirements about optical or mechanical qualities. However, as mentioned above, because the behavior of sapphire varies depending on orientations, random orientation might be subject to spontaneous variations of optical properties and other properties in the final product.

Before the cutting or slicing procedure, sometimes the manufacturer would grow the bulk sapphire crystal of a specific orientation. For example, the bulk sapphire designated to produce a c-cut sapphire window will be grown with an orientation that maximizes the utilization efficiencies of the c-planes.

Curves:

1. Transmission of Sapphire Windows without Coating from UV to 1100nm

2. Transmission of Sapphire Windows without Coating from 2.5μm to 8.0μm

3. Transmission Curves of UV-Grade Sapphire Windows

a. Optical transmission curves of our UV-grade sapphire windows (uncoated)

b. Optical transmission curves of UV-grade sapphire windows D57.15x4mm (uncoated)

c. Optical transmission curves of UV-grade sapphire windows D65.15x4mm (uncoated)